Making Precast Concrete Faster, Easier and Cheaper

Cheaper, Faster, Easier — Without Sacrificing Performance.

Replace Steel Reinforcement in Your Precast Concrete

BarChip works by distributing tens of thousands of high tensile strength fibres throughout the concrete mix, delivering better crack control and durability. If you’re still rolling out steel for your precast concrete, it’s time to make your life easier and switch to BarChip fibre.

The World’s Best Fibre for Precast Concrete

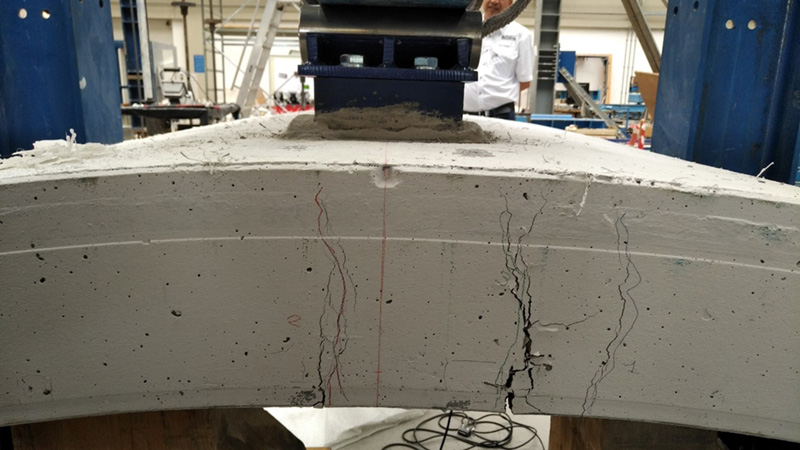

BarChip48 is recognised the world over as the number one fibre for precast concrete. In comparison testing of more than 20 different fibres, BarChip delivers the best result in EN14651 and AS3600 beam testing.

Get Fibre Concrete Designs in Minutes

Using custom built tools based on ACI 544 and TR34 design methods, you can quickly determine the feasibility of BarChip fibre in your project. BarChip’s free to use design app is fast, simple to use and lets you generate reports straight from the app in just minutes. Suitable for flooring, paving and shotcrete applications.

Low Carbon Precast Concrete Design

One of the most significant advantages of using BarChip fibres in precast concrete is potential reductions in carbon footprint.

Lower Carbon Footprint

Typical dose rates of BarChip fibre have a carbon footprint of 6 to 12 kg of carbon per cubic metre of concrete, a massive reduction compared to steel alternatives. BarChip carbon data is supported by published EPDs.

Reduced Concrete Usage

In some precast applications, the corrosion free reinforcement and the improved crack control of BarChip fibre can allow for thinner precast structures. Reduced concrete consumption translates into massive carbon savings for precast manufacturers.

Where is Fibre Reinforced Precast Concrete Used?

BarChip fibre reinforced precast concrete is suitable for use in nearly every type of precast concrete, from architectural panels to major infrastructure works and smaller commercial or residential works.

Precast Tunnel

Segments

Invert

Segments

Water and Wastewater Tanks

Septic

Systems

Electrical

Cabinets

Ballast Pads

Burial Vaults

Walls

and Barriers

Seating

Manholes

Railway

Track Slab

Frequently Asked Questions

Does fibre reinforcement reduce the cost of precast concrete?

Yes. Fibres eliminate the time required for installation of steel reinforcement, improving production efficiency and significantly reducing labour costs.

Do fibres reduce precast concrete manufacturing times?

Yes. Installing steel reinforcement in precast concrete mould is a physical and time consuming process. By eliminating this step, BarChip saves significant time for precast concrete manufacturers.

Can macro synthetic fibre replace steel reinforcement in precast concrete?

Yes. BarChip fibre increases the post crack residual capacity of concrete. The improved “toughness” allows fibre to replace traditional steel in a wide variety of precast concrete applications.

What types of precast concrete use macro synthetic fibre reinforced concrete?

Almost all precast concrete can incorporate fibre reinforcement. BarChip fibre has been successfully used in a wide range of precast concrete applications, including tunnel segments, concrete pipes, box culverts, water tanks, septic systems, noise barriers, retaining walls, cabinets, pits, troughs and more.

How much fibre is needed to reinforce precast concrete?

BarChip is typically dosed between 3kg and 6kg per cubic metre in precast concrete. Dose rates can increase for very high performance applications like precast tunnel segments.

What is the best fibre for precast concrete?

BarChip 48 is widely recognised as a leading global fibre for precast concrete given its superior performance in low deflection testing. Other BarChip fibres can also meet the performance needs of many precast elements.

What is the minimum thickness for fibre reinforced precast concrete?

BarChip is corrosion free, with no need for minimum concrete cover. As such, the thickness is determined by performance and not durability. BarChip has reinforced precast elements as thin as 20mm.

Why are fibres used in Precast Concrete?

Macro synthetic fibres make precast concrete faster to produce, cheaper and more durable than traditional steel reinforcement.

Get in touch for a personal information session about your next project. One of our concrete fibre experts will guide you through the following 4 keys items: