Macro Synthetic Fibre Reinforced Concrete – Low Cost, Low Carbon, Corrosion Free.

BarChip Fibre for Concrete

BarChip Designs and Manufactures High Performance Macro Synthetic Fibre for use in Fibre Reinforced Concrete and Shotcrete.

Our concrete fibres:

BarChip fibre is globally recognised for its performance and reliability, and for the expert support delivered by the BarChip team. From fibre selection to design, application and quality control, BarChip has you covered. Make your life easier and change to a better concrete reinforcement system today.

BarChip Fibre Concrete: Used Across All Industries

BarChip fibre concrete reinforcement is used in nearly every sector of the construction industry. Since 1995, BarChip has reinforced more than 450 civil tunnels, over 15 million square metres of flooring works, thousands of kilometres of mine development, and railway track slab on 4 continents. If it’s made from concrete, chances are BarChip can reinforce it.

Find Us On LinkedIn

Latest News

Benefits of BarChip

Fibre Reinforced Concrete

BarChip delivers value to our customers through improved concrete performance and durability, reduced costs, and easier jobsite processes.

Increased Performance

Faster Construction

Easier to Use

Corrosion Free

Increased Durability

EPD Certified Low Carbon

Increased Safety

Reduced Maintenance

Reduced Construction Cost

BarChip Makes Concrete Cheaper and Easier, Without Sacrificing Performance.

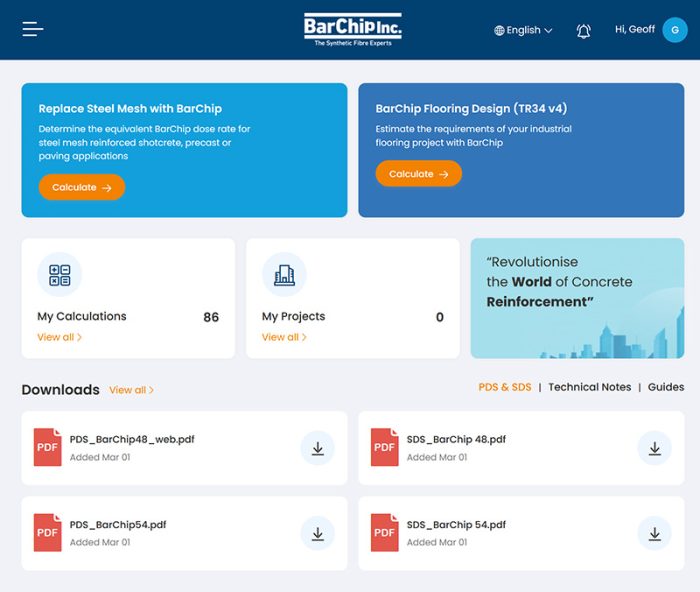

Get Fibre Concrete Designs in Minutes

Using custom built tools based on ACI 544 and TR34 design methods, you can quickly determine the feasibility of BarChip fibre in your project. BarChip’s free to use design app is fast, simple to use, and lets you generate reports straight from the app in just minutes. Suitable for flooring, paving and shotcrete applications.

Trusted by the World’s Leading Brands

BarChip users are a who’s who of global construction firms, mining houses and retail giants. From critical infrastructure to concrete pavements, BarChip’s high performance macro synthetic fibres are trusted to deliver superior concrete reinforcement solutions.

Technical Notes

Frequently Asked Questions

What is fibre reinforced concrete?

Fibre reinforced concrete is a composite material made by adding discrete fibres such as steel, synthetic, or glass to concrete. These fibres enhance crack resistance, toughness, and durability, making the concrete more resilient under tensile stress and dynamic loads. Find out more in our Knowledge Centre article: “What is Fibre Reinforced Concrete? A Beginner’s Guide”.

What types of fibre are used in concrete?

Numerous types of fibres are used in concrete, from cellulose to carbon fibre, natural fibres, synthetic and steel. The main types of fibres used in concrete are macro synthetic fibre, micro synthetic fibre and steel fibre.

What is macro synthetic fibre concrete reinforcement?

Macro synthetic fibre is a high-performance polymer-based concrete reinforcement. Typically made from polypropylene, it enhances crack control, toughness and durability. Macro synthetic fibres replace steel mesh in many concrete applications, offering corrosion prevention and easier placement during construction.

Can macro synthetic fibre replace steel in concrete?

Yes, macro synthetic fibre delivers equal or greater post crack residual strength compared with steel, and enhances durability by eliminating the risk of corrosion. Macro synthetic fibres are commonly used in place of steel mesh or steel fibres in industrial flooring, shotcrete, precast elements and pavements.

Where is fibre reinforced concrete used?

Globally, the most common applications of fibre reinforced concrete are precast concrete, paving, industrial flooring, tunnel linings, road pavements, track slab, ground support and other civil applications. Use of fibre in the broader concrete market and specialty applications is becoming increasingly more common.

Where should fibre reinforced concrete be used?

Fibres can be used as reinforcement in nearly all concrete applications. Any applications that require improved toughness and ductility or enhanced durability, such as applications exposed to harsh environments, should always consider macro synthetic fibre reinforced concrete before traditional solutions.

What are the benefits of fibre reinforced concrete?

Fibre reinforcement improves the post crack residual strength of concrete, providing better crack control, increased ductility and toughness, and improved durability. BarChip macro synthetic fibres replace traditional steel reinforcement, speeding up construction, cutting costs, and reducing the carbon footprint. Its versatility makes it ideal for applications such as industrial floors, tunnels, and precast elements, offering both performance and sustainability.

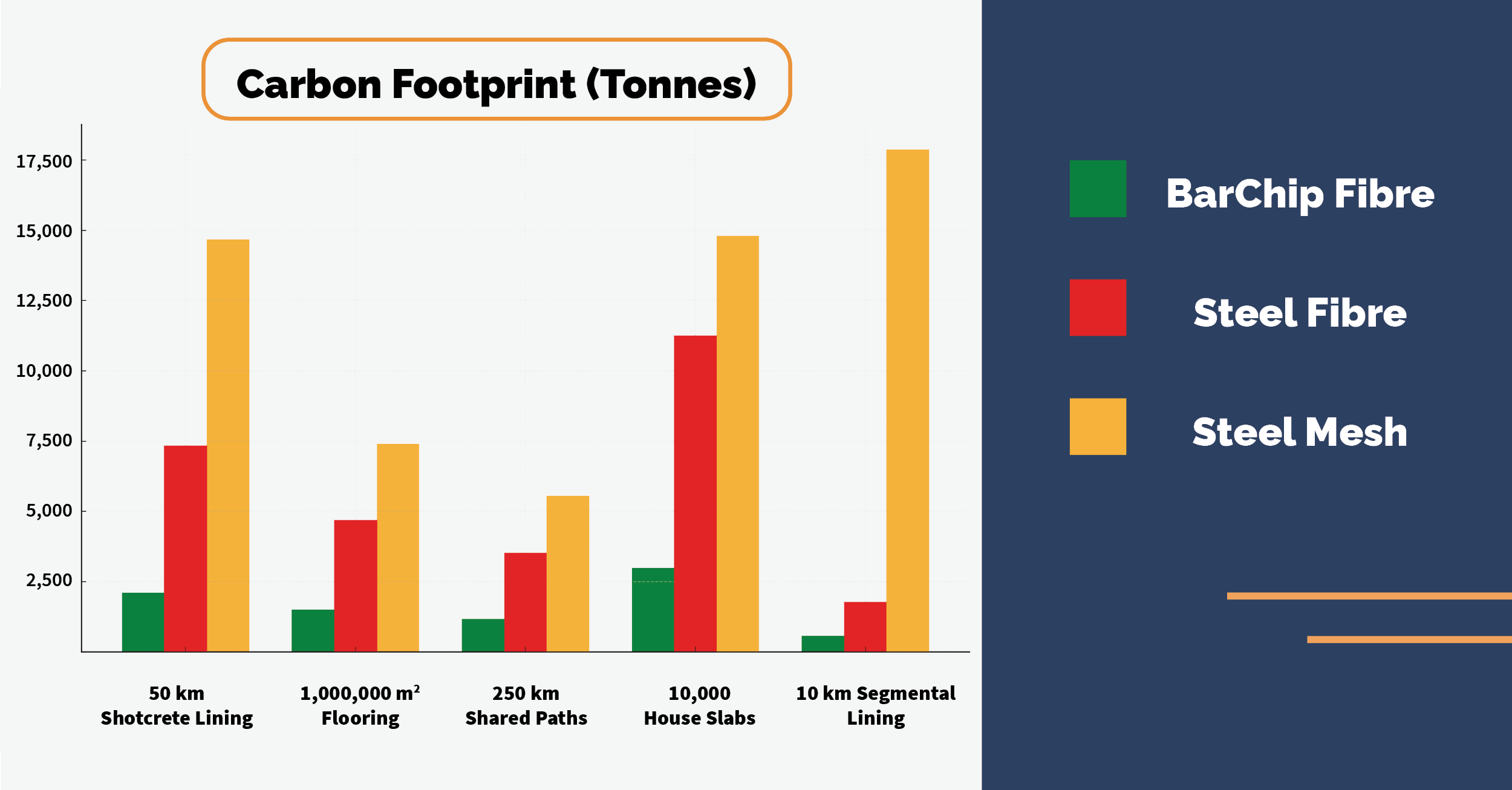

Does fibre reinforcement reduce the carbon footprint of concrete?

Yes, fibre reinforcement, particularly macro synthetic fibres, can enable significant reductions in the carbon footprint of concrete structures through both direct material savings and potential reductions in concrete consumption. Beyond direct carbon reductions, modelling also shows that BarChip has a positive impact on sustainability outcomes in the supply chain, for the community and for workers during construction and in service life durability outcomes.

Get in touch for a personal information session about your next project. One of our concrete fibre experts will guide you through the following 4 keys items: