Up to 450,000 BarChip fibres are evenly distributed in every cubic metre of concrete. Not one will ever suffer from corrosion

BarChip synthetic fibre concrete reinforcement is a high performance polypropylene fibre used as structural reinforcement in concrete and shotcrete.

The BarChip reinforcement system works by distributing hundreds of thousands of high tensile strength fibres throughout the entire concrete mix. They reinforce every part of the concrete structure, front to back and top to bottom, leaving no vulnerable unreinforced concrete cover.

BarChip Fibre Concrete Benefits

- Redistributes load – increased ductility / toughness

- Eliminates corrosion – long term durability

- Reduces maintenance costs and rehabilitation closures

- Eliminates set-up of steel mesh

- Reduces development cycle times

- Improves precast production speeds up to 50%

- Increases abrasion and impact protection

- 70% reduction in carbon footprint compared to steel

- Safer and lighter to handle than steel

- Reduced wear on concrete pumps and hoses

- BarChip fibre is UV stabilised to resist solar deterioration

- Weather proof packaging on multi-stack UPVC pallets

BarChip 48

Optimised for precast, paving and flooring works

BarChip MQ58

Optimised for paving and flooring works

BarChip 54

Optimised for sprayed concrete works

BarChip 60

Optimised for sprayed concrete works

BarChip R50

Incorporating recycled materials

BarChip R65

Incorporating recycled materials

See Below For PDS and SDS

| Characteristic | BarChip 2024 | BarChip 48 | BarChip 54 | BarChip 60 | BarChip MQ58 | BarChip R50 | BarChip R65 | Standard |

|---|---|---|---|---|---|---|---|---|

| Fibre Class II | For structural use in concrete, mortar and grout | EN 14889-2 | ||||||

| Tensile Strength | 680 MPa | 640 MPa | 640 MPa | 640 MPa | 640 MPa | 610 MPa | 610 MPa | JIS L 1013/ISO 2062 |

| Young’s Modulus | 10 GPa | 12 GPa | 12 GPa | 12 GPa | 10 GPa | 10 GPa | 10 GPa | JIS L 1013/ISO 2062 |

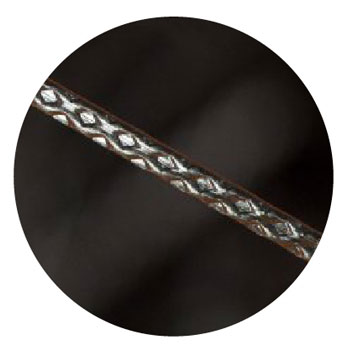

| Anchorage | Continuous Embossing | |||||||

| Base Material | Virgin Polypropylene | Bi-Component Polymer | Virgin and Recycled Polypropylene | |||||

| Alkali Resistance | Excellent | |||||||

| Length | 24 mm | 48 mm | 54 mm | 60 mm | 58 mm | 48 mm | 65 mm | |

| CE Certification | 1029 – CPR – GB19/964030 | 1029 – CPR – GB19/964030 | ||||||

| ISO 9001:2015 Certification | 0044943 | |||||||

Find Out Which Fibre Is Best For You!

BarChip 48 is a high performance structural synthetic fibre concrete reinforcement, optimised for pavements, industrial floors and precast elements.

%

Increase in Daily Floor Completion Rates

%

Increase in Precast Production Speeds

%

Reduction in Corrosion

BarChip 54 is a high performance structural synthetic fibre concrete reinforcement, optimised for sprayed concrete (shotcrete). BarChip 60 is optimised for sprayed concrete (shotcrete) with large displacements.

%

Increase in Sprayed Concrete Application Speed

%

Reduction in Fibre Handling Costs

%

Reduction in Corrosion

BarChip MQ58 is a high performance structural synthetic fibre concrete reinforcement, optimised for pavements and industrial floors. The unique composition of BarChip MQ58 enables a perfect, fibre free finish on your concrete works.

%

Reduction in Industrial Floor Costs

%

Increase in Daily Floor Completion Rates

%

Reduction in Corrosion

BarChip R series is an environmentally friendly concrete fibre reinforcement from BarChip Inc. Made with recycled materials, BarChip R series delivers massive carbon savings to your concrete works, without sacrificing performance.

%

Increase in Sprayed Concrete Application Speed

%

Reduction in Fibre Handling Costs

%