Design With Confidence

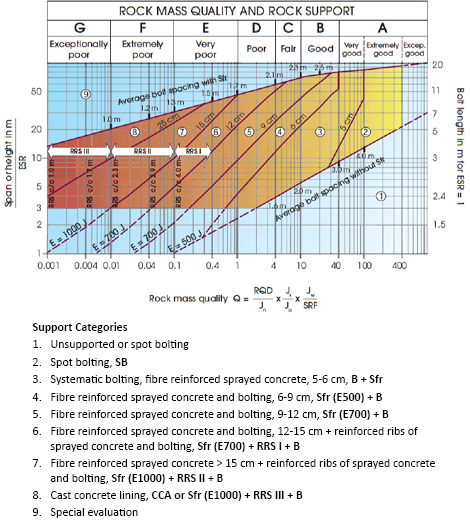

Barchip’s macro synthetic fiber concrete reinforcement conforms with international design methodologies and standards from bodies such as DBV, RILEM, CNR, ACI, ITAtech and the UK Concrete Society.

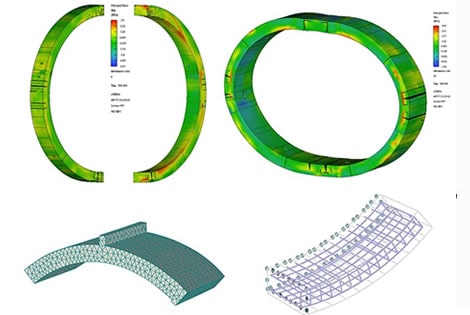

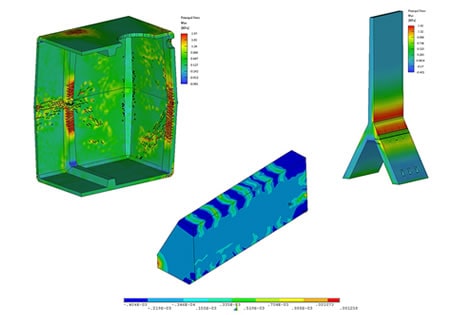

Our experienced team can guide you through the design process, providing comparative analysis, structural design and where appropriate complex finite element analysis (FEA). When you design with Barchip, you design with confidence.

Background information on the use of macro synthetic fiber reinforced concrete is given in; The UK Concrete Society’s TR 65 – Guidance on the use of Macro-synthetic FRC, April 2007.

Latest Projects

Jointless Floor With Macro Fibre

JOINTLESS Flooring Solutions with BarChip macro synthetic fibre. HelloParks 46,500 m2 PT2 Big Box warehouse is a prime example of fibre reinforced jointless flooring without steel reinforcement.

Key Benefits of Fibre Reinforced Precast Concrete

BarChip is a proven game-changer for precast concrete. We look at the key benefits that make fibres ideal for modern precast concrete construction.

Fibre Reinforced Shotcrete Lining- Divaca-Koper Rail Tunnel

BarChip54 and BarChipR65 were used across all 8 tunnels of the Second Track, with over 850 tonnes used to reinforce more than 150,000 m3 of shotcrete.