Fibre Free Surface Finish.

Jointless Flooring Solutions.

BarChip Flooring Manual

Get a Design for Your Project

Complete Barchip’s “Design Information Sheet” to determine your Barchip synthetic fiber requirements.

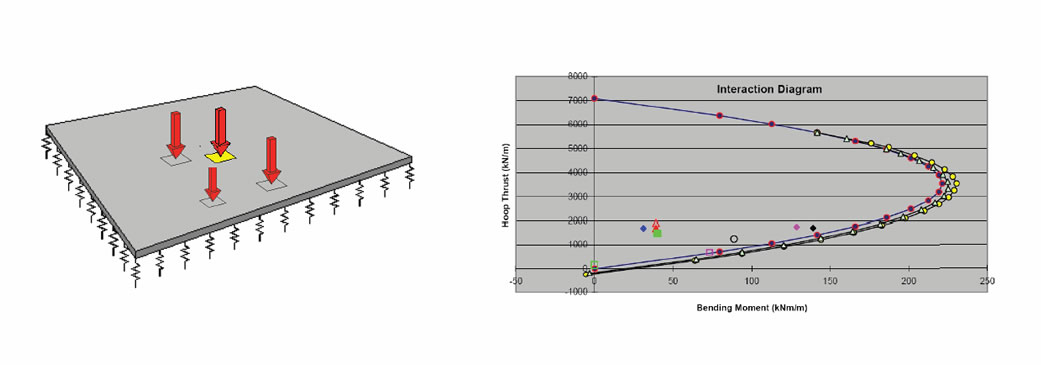

Design With Confidence

Barchip can incorporate macro synthetic fiber design solutions for a wide variety of construction methodologies, whether they be from institutes such as RILEM, CNR, UK Concrete Society, ACI or others.

Whatever relevant international code or guideline applies, Barchip ensures that all BarChip fiber reinforced floors are designed to the required performance criteria of each unique project. This method guarantees not only compliance with relevant building statutes but also optimises the design and provides the best product and the lowest possible price.

LATEST PROJECTS

Creep of Fibre Reinforced Concrete

11 Key Facts on the Creep of Fibre Reinforced Concrete: Your Ultimate Guide on Fibre Concrete Creep.

Jointless Floor With Macro Fibre

JOINTLESS Flooring Solutions with BarChip macro synthetic fibre. HelloParks 46,500 m2 PT2 Big Box warehouse is a prime example of fibre reinforced jointless flooring without steel reinforcement.

Fibre Reinforced Insulated Concrete Forms (ICF)

BarChip fibre was used to reinforce the Jackon THERMOMUR insulated concrete forms from BEWI at Villa Fonnes in Norway.