Over 4 Million Square Metres of Flooring Worldwide

BarChip Flooring Manual

Over the past 20 years thousands of companies have made the switch to the synthetic fiber reinforcement system, which delivers multiple benefits to your concrete asset;

- Eliminates corrosion of crack control mesh

- Eliminates the risk of concrete cancer

- Reduces crack propagation

- Increases production speeds as much as 50%

- Increases flexural toughness

- Increases impact resistance

- Increases fatigue strength

- Reduces labour costs

- Reduces material handling and transport costs

- Reduces equipment maintenance

- Provides up to 70% reduction in carbon footprint

Get a Design for Your Project

Complete Barchip’s “Design Information Sheet” to determine your Barchip synthetic fiber requirements.

Design With Confidence

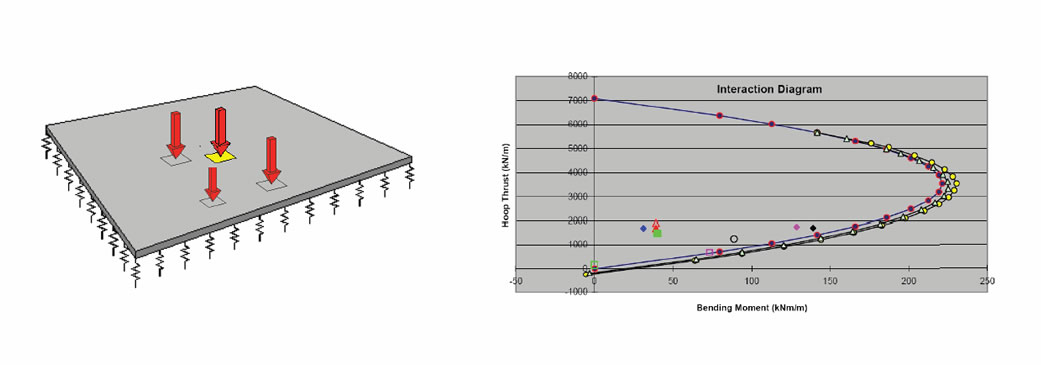

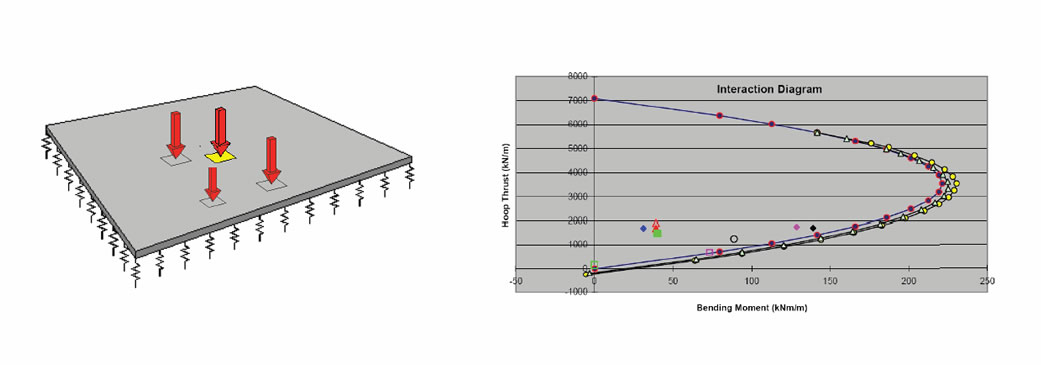

Barchip can incorporate macro synthetic fiber design solutions for a wide variety of construction methodologies, whether they be from institutes such as RILEM, CNR, UK Concrete Society, ACI or others.

Whatever relevant international code or guideline applies, Barchip ensures that all BarChip fiber reinforced floors are designed to the required performance criteria of each unique project. This method guarantees not only compliance with relevant building statutes but also optimises the design and provides the best product and the lowest possible price.

LATEST PROJECTS

Taurus Armas Factory Floor

The total expansion of 22,000 m2 allowed Taurus to increase production by 50% and included logistics and distribution facilities, engineering, laboratories and offices.

Amazon Fulfilment Centre

BarChip MQ58 was used as the primary concrete reinforcement in Amazon’s 41,180 m2 fulfilment centre.

BarChip Flooring Design Tables

BarChip’s flooring design tables allow you to quickly check required dose rate and thickness of concrete flooring and pavements.