Full-Scale Testing of

BarChip Fibre Reinforced

Concrete Tunnel Segments – Part 1

Full-Scale testing of BarChip fibre reinforced tunnel segment

Who says you can’t use macro synthetic fibre in precast concrete tunnel segments?

There’s a nasty rumour running around the tunnelling industry that macro synthetic fibres can’t be used in precast tunnel segments. Doesn’t adhere to Model Code, it creeps, the performance isn’t high enough; these are just some of the reasons we’ve heard. To be fair, the arguments aren’t new, but considering BarChip has already been used to reinforce 5 different segmentally lined tunnels, we thought it might have disappeared. It hasn’t, so we sought to academically prove through full-scale segment testing at the University of Brescia, Italy, that BarChip can be use in segmental tunnel linings. The goal was simple, prove that BarChip was suitable for use according to the design requirements of:

- A known tunnel, and

- The Model Code 2010.

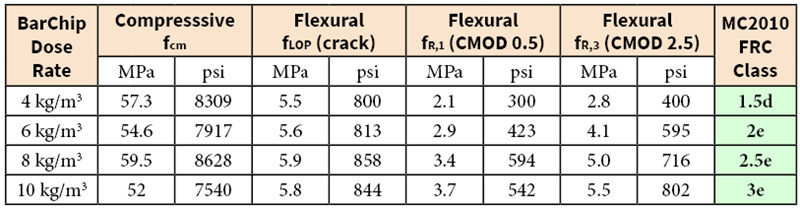

Material characterisation showed BarChip EN 14651 beams dosed at 4, 6, 8 & 10 kg per cubic metre meets performance classes 1.5d, 2e, 2.5e and 3e respectively in Model Code 2010 and meet the requirements of the reference tunnel.

Table 1: Summary of beam results from BarChip FRC material characterisation testing.

Using the recently completed Scilla Tunnel in Italy as a reference, the research team at Brescia cast 10 full-scale segments reinforced with a traditional steel cage system, a hybrid steel and BarChip fibre system and a BarChip fibre only system. Full scale testing in flexure and point load showed that both the BarChip reinforced and Hybrid systems could meet the performance requirements of the chosen tunnel, with the Hybrid system performing remarkably similar to full cage reinforcement but with 68% less steel.

Figure 1: Full-Scale testing of BarChip fibre reinforced tunnel segments in flexural (left), and point load (right).

In this series of articles we’ll review this ground breaking research in detail and show without a doubt that BarChip macro synthetic fibre is suitable for use in precast tunnel segments.

Reference Tunnel – Scilla Tunnel, Italy

For practical reasons, the recently completed Scilla power cable tunnel in Calabria, Italy, was chosen as the reference tunnel. It was designed according to current Italian standards, the engineering team at Brescia were familiar with the design, and moulds could be acquired from the project for full scale segment manufacturing. The tunnel is one of the main structures of the new power line between Scilla and Calabria.

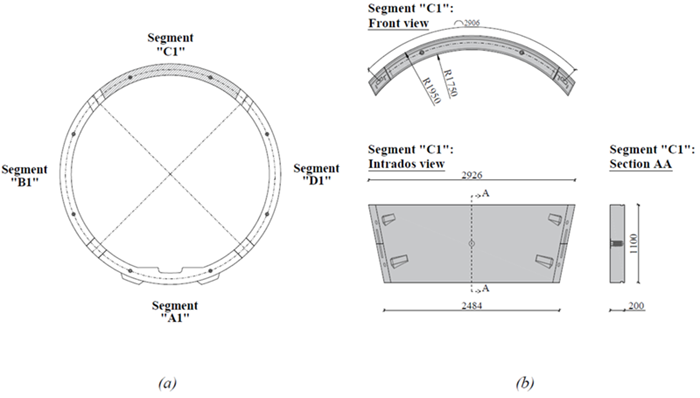

The 2800 m long tunnel has an internal diameter of 3500 mm and a thickness of 200 mm, for an aspect ratio of 17.5. Trapezoidal segment C1 was chosen for the study, having an average arc length of 2906 mm and width of 1100 mm, yielding a segment aspect ratio of 14.5.

Figure 2: Scilla precast segmental tunnel lining: (a) segmental ring details and (b) adopted segment.

The required flexural capacity for Serviceability Limit State (SLS) for demoulding, storage, positioning and final stage was 8.81 kNm. The Ultimate Limit State (ULS) was 11.45 kNm, which was assumed to guarantee worker safety in exceptional situations.

Reinforcement Solutions

Extensive material mechanical testing was conducted to determine an appropriate dose rate and mix design. The results of the study can be seen here – Material Mechanical Characterisation.

Ten full-scale segments were cast and tested in flexure to determine temporary loading conditions, and in point loading to determine performance during TBM jacking. Three different reinforcement solutions were used:

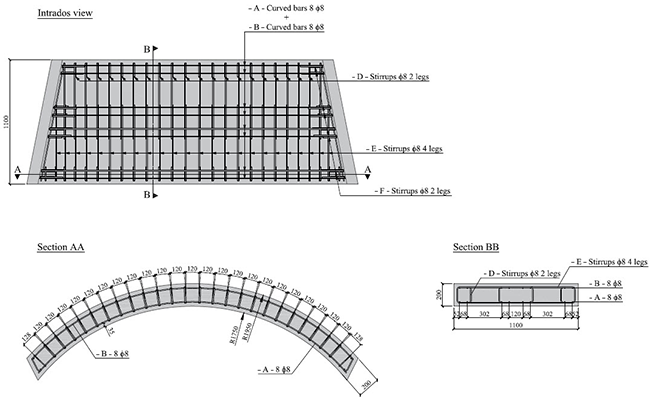

- Traditional reinforcement solution (RC Segments).

- 110 kg/m3 of steel bar (see details in Figure 3).

- Typical longitudinal reinforcement ratio of 0.23%

- Minimum shear reinforcement acc. to EC2.

- Local stirrups for splitting stresses.

- Two segments cast. RC-B (tested in flexure) and RC-P (tested in point load).

- BarChip fibre solution (MSF Segments).

- 8 kg/m3 of BarChip 48 macro synthetic fibre as the sole reinforcement of the segments

- 4 segments cast. BarChip MSF-B1 and BarChip MSF-B2 (tested in flexure) and BarChip MSF-P1 and BarChip MSF-P2 (tested in point load).

- 8 kg/m3 of BarChip 48 macro synthetic fibre as the sole reinforcement of the segments

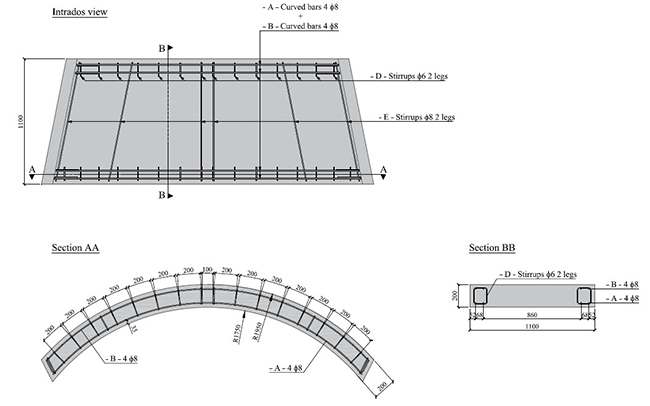

- Hybrid reinforcement solution (HYB Segment).

- 35 kg/m3 of steel bar and 8 kg/m3 of BarChip 48 fibre (see details in Figure 4).

- A minimum amount of longitudinal rebars concentrated in two chords, yielding a reinforcement ratio of 0.11%.

- BarChip 48 macro synthetic fibre used as minimum shear reinforcement and as reinforcement against splitting crack development.

- 4 segments cast. HYB-B1 and HYB-B2 (tested in flexure) and HYB-P1 and HYB-P2 (tested in point load).

Figure 3: Reinforcement details of RC Segment (dimensions in mm).

Figure 4: Reinforcement details of the Hybrid Segment (dimensions in mm)

If you want to discuss the results in more details contact us at info@barchip.com.

Follow the links below to see the results of the full-scale testing program.

- BarChip Tunnel Segment Testing Part 2 – Material Mechanical Characterisation (Beam Testing & Concrete Mix Design)

- BarChip Tunnel Segment Testing Part 3 – Full-Scale Flexural Testing

- BarChip Tunnel Segment Testing Part 4 – Full-Scale Point Load Testing (coming soon)