100% BarChip Fibre Reinforced Concrete Tunnel Segments

An American First!

BarChip Fibre Reinforced Concrete at the Blacksnake Creek Stormwater Tunnel.

In an American first, BarChip fibre reinforced concrete has been used as the sole reinforcement for a segmental tunnel lining at the Blacksnake Creek Stormwater Separation Project.

Project Owner: City of St. Joseph, Missouri.

Project Designer: Black and Veatch Corporation.

Project Contractor: Super Excavators, Inc.

Project Segment Manufacturer: CSI Tunnel Systems.

To meet regulatory requirements of the Environmental Protection Agency and the Missouri Department of Natural Resources, the city of St. Joseph, MI, will separate and redirect a portion of the stormwater runoff from the Blacksnake Creek watershed to a dedicated outfall near the Missouri River. A key element of the plan is the Blacksnake Creek Stormwater Separation Tunnel.

- 2.0 km (1.3 miles) in length with an Internal diameter of 2.75 m (9 feet).

- Excavated by EPB TBM.

- The TBM was launched in a 16 m (53 foot) dual baffle drop shaft with 11 m (37 foot) internal diameter.

- A BarChip fibre reinforced concrete “half-ring” was used to push TBM into the excavation.

- Constructed in soft and mixed ground including soils and shale and combinations of both at interfaces.

- Advancing at a single shift daily rate of 12 to 14 meters.

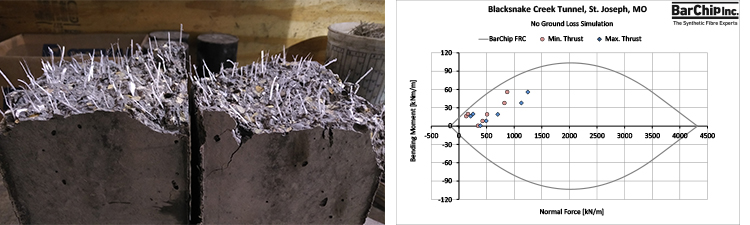

BarChip Fibre Reinforced Concrete Tunnel Segment After Production

BarChip Fibre Reinforced Concrete Segmental Lining

- Composed of 6 trapezoidal segments with rubber gasket frames.

- Segment dimensions are 190.5 mm (7.5 inches) thick and 1219.2 mm (48 inches) wide, with an internal diameter of 2.7 m (9 feet) and an aspect ratio of 8.1.

- Concrete class of C40/50 (f’c 48 MPa) at 28 days age, with a stripping strength of 14 MPa (2030 psi).

- Minimum compressive strength of 41.4 MPa (6,000 psi), minimum flexural tensile strength at 28 days of 4.62 MPa (670 psi), and minimum residual flexural tensile strength of 3.17 MPa (460 psi).

The 100% BarChip fibre reinforced segments are the first of their kind to be used in North America. The segments are placed using a mechanical segment erector located in the trailing shield and are manually bolted together.

Placement of a BarChip Fibre Reinforced Concrete Tunnel Segment

Installed BarChip Fibre Reinforced Concrete Tunnel Segments

BarChip macro synthetic fibre was chosen as the sole reinforcement for the segments primarily to comply with America Iron and Steel provisions. Based on previous experience with BarChip fibre reinforced concrete in the Euclid Creek CSO tunnel, Segment manufacturer CSI Tunnel Systems, Inc. were comfortable in recommending BarChip for the Blacksnake tunnel segments. There were no objections to the use of BarChip fibre reinforcement provided the segments met the performance specifications.

In-Situ Performance of BarChip Fibre Reinforced Concrete Tunnel Segments

As of March 2019, the tunnel drive on the Blacksnake Creek Stormwater Separation Project is 30% complete and the initial tunnel drive installation has proven that BarChip fibre reinforced concrete tunnel segments are robust enough to withstand the temporary load cases of;

- Post-production demoulding, hoisting and stacking,

- Transportation and transfer to on-site storage, and

- Handling and installation with a single point mechanical erector.

Furthermore, the half-ring segment sections used in the shaft for the launching process were inspected after the initial push with no damage recorded.

Performance Testing of BarChip Fibre Reinforced Concrete

The overall performance of the BarChip fibre reinforced concrete segments has surpassed the contractor’s expectations. The indicating factors of the performance of the machine, durability and robustness of the segments, and performance of the crew all facilitate meeting the project goals.