Fibre Reinforced Shotcrete Lining- Divaca-Koper Rail Tunnel

BarChip54 and BarChipR65 were used across all 8 tunnels of the Second Track, with over 850 tonnes used to reinforce more than 150,000 m3 of shotcrete.

BarChip54 and BarChipR65 were used across all 8 tunnels of the Second Track, with over 850 tonnes used to reinforce more than 150,000 m3 of shotcrete.

BarChip macro synthetic fibre helps Parramatta Light Rail deliver world-class sustainable infrastructure, reducing the carbon footprint of the concrete track slab by 4,815 tonnes of CO2e and reducing labour costs by 15%.

BarChip fibre was used to reinforce the Jackon THERMOMUR insulated concrete forms from BEWI at Villa Fonnes in Norway.

The total expansion of 22,000 m2 allowed Taurus to increase production by 50% and included logistics and distribution facilities, engineering, laboratories and offices.

BarChip MQ58 was used as the primary concrete reinforcement in Amazon’s 41,180 m2 fulfilment centre.

BarChip fibre reinforced shotcrete was used for the walls of the Warland St Trunk Drain, recovering construction time lost to bad weather.

In an Australian first, BarChip fibre was used as the primary reinforcement in the primary shotcrete lining of the commuter rail tunnels at Brisbane’s Cross River Rail.

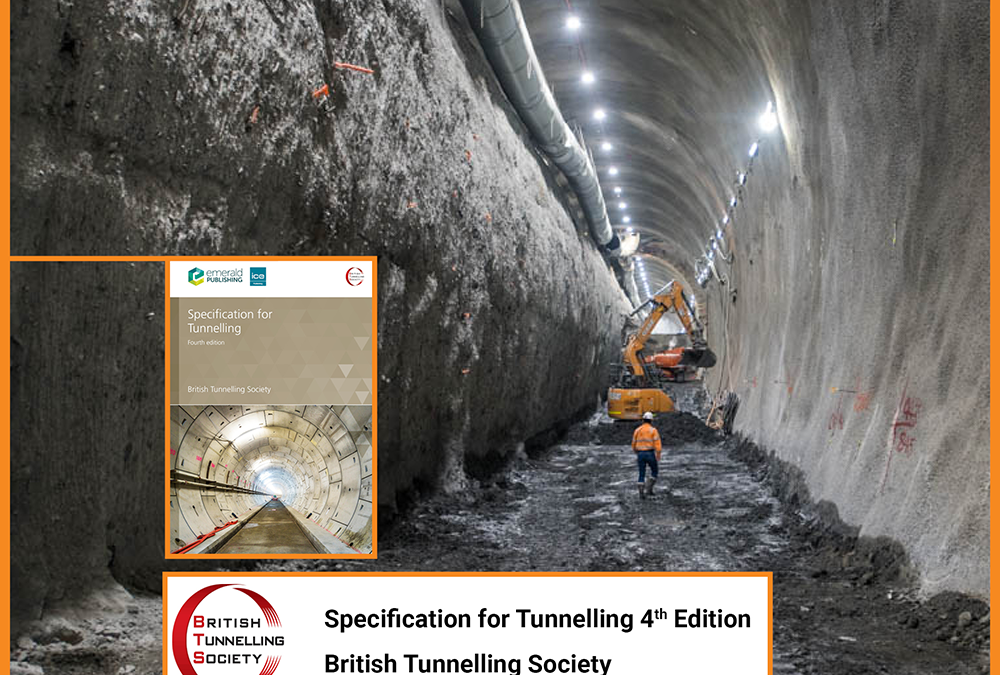

The British Tunnelling Society has released the fourth edition of Specification in Tunnelling. You can download the fourth edition here.

BarChip’s flooring design tables allow you to quickly check required dose rate and thickness of concrete flooring and pavements.

BarChip reduce carbon footprint of shotcrete ground support by over 70 million kg of carbon.

We are excited about the opportunities this facility brings, both in the global construction market and throughout Latin America.

BarChip fibre eliminates the need for steel mesh in the 4,500 m2 concrete screed overlay of Primark’s flagship Romanian store.