Sustainable Concrete Solutions With BarChip Fibre

When it comes to sustainability, decarbonisation and low carbon activities often get most of the attention. Yet BarChip enables sustainable concrete solutions across the entire life cycle, contributing far more to the sustainability outcomes of modern construction projects.

From supply chain benefits to reduced material consumption, community outcomes and the service life of concrete, BarChip macro synthetic fibre positively impacts almost every stage of the construction life cycle.

Read on and discover the seven ways BarChip transforms construction projects for the better.

Resource Efficient Supply Chain With BarChip Fibre

The process of transforming plastic pellets into BarChip fibre is significantly less resource intensive compared to producing steel reinforcement from iron ore. BarChip manufacturing uses more than 90% less freshwater and over 80% less non-renewable energy than traditional steel production. These efficiencies align with global sustainability goals, minimizing resource consumption and promoting a more efficient, environmentally responsible supply chain.

Low Carbon Concrete Reinforcement

BarChip macro synthetic fibre is a low carbon reinforcement solution, with a typical carbon footprint of just 6 kg to 12 kg per cubic metre of concrete. In comparison, steel fibres typically range from 19 kg to 37 kg, while steel mesh reinforcement often exceeds 100 kg of carbon per cubic metre of concrete.

By switching to BarChip fibre, contractors can significantly reduce the carbon footprint of their reinforcement. Additionally, BarChip can enable designs that use less concrete, massively amplifying potential carbon savings.

Efficient Material Use With Fibre Reinforced Concrete

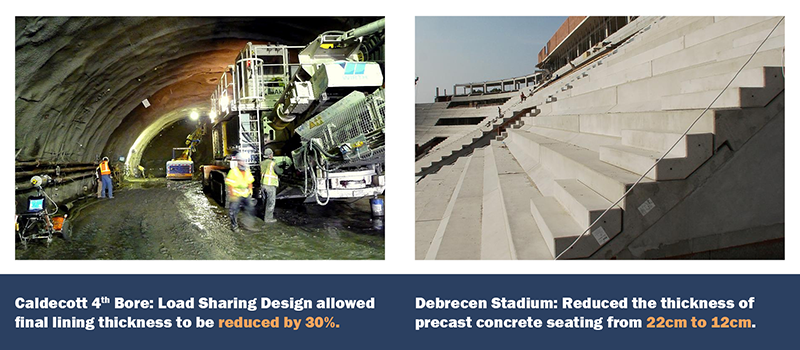

BarChip can eliminate the need for extra concrete cover or sacrificial layers that protect against corrosion, enabling thinner concrete cross sections in flooring and precast applications.

In tunnelling works, fibre reinforced shotcrete follows the ground profile without overspray, reducing waste and improving efficiency. BarChip primary linings can be used as permanent linings in load sharing designs that reduce final lining thickness. Where waterproof membranes are used, BarChip reinforced primary linings eliminate the need for smoothing layers typically required with steel fibre reinforcement.

By reducing concrete consumption, BarChip helps deliver measurable environmental benefits while also driving noticeable cost savings for projects.

Minimizing Community Impact Through Smarter Construction

BarChip fibre reinforced concrete enables faster construction timelines, minimizing disruption to local communities. Unlike steel, BarChip is pre-mixed with concrete and delivered ready for use, significantly reducing the number of site deliveries. Fewer deliveries mean less traffic congestion, lower noise levels and reduced emissions, creating a healthier environment around project areas.

By reducing costs, BarChip supports more efficient public infrastructure spending, maximizing value for communities and contributing to sustainable infrastructure solutions that benefit both people and the environment.

Safer, Healthier Job Sites With Fibre Reinforced Concrete

BarChip eliminates the need for handling and placing steel mesh, reducing worker fatigue, lowering physical strain and removing trip hazards on-site.

In mechanised tunnelling works, BarChip fibre reinforced shotcrete removes the need for workers to operate under unsupported ground, a critical improvement in worker safety. BarChip prioritizes worker safety by making concrete processes simpler, safer and less physically demanding.

Life Cycle Performance of BarChip Fibre Reinforced Concrete

BarChip’s combination of corrosion prevention and ductile performance enhances the durability of concrete structures. By controlling cracks and eliminating corrosion, BarChip reduces maintenance requirements and repair costs over time.

This extended service life translates into lower life cycle costs and enhanced sustainability throughout the structure’s life. It also demonstrates the importance of sustainability in concrete reinforcement, where material choice directly impacts durability, maintenance and long-term environmental outcomes.

End-of-Life Solutions for Sustainable Concrete

BarChip fibre reinforced concrete can be processed and reused in secondary applications such as road subbase or general fill, reducing the volume of material sent to landfill. Its ability to be reused aligns with circular economy principles, promoting resource efficiency and reducing environmental impact at the end of a structure’s service life.