Top 5 Advantages of Synthetic Fibre Reinforced Shotcrete

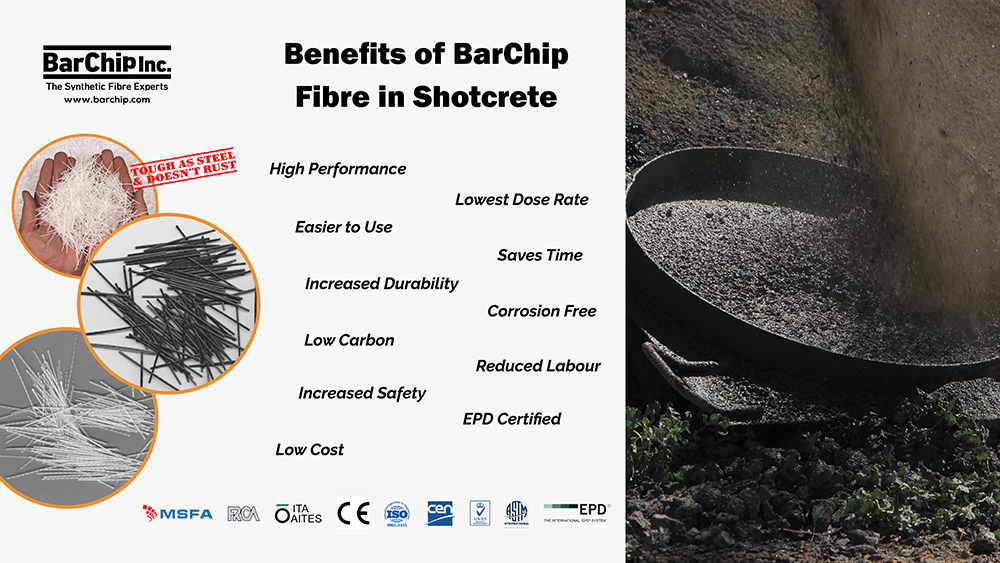

Fibre reinforced shotcrete has been a game-changer in the construction industry, particularly in slope stabilisation, cavern support and tunnelling applications. BarChip macro synthetic fibres improve the performance of shotcrete while addressing the challenges of harsh environments and complex ground geometries, making it the preferred alternative to traditional steel reinforcement.

Here are the top five advantages of using BarChip synthetic fibre reinforced shotcrete:

1. Corrosion-Free Durability

BarChip fibres are corrosion free, unlike steel, which is prone to rusting in high moisture or chemically aggressive environments. Corrosion can severely weaken steel reinforced shotcrete (fibre or traditional mesh), leading to costly repairs and even structural failure. BarChip fibres do not corrode, reducing maintenance and prolonging the service life of the structure. Corrosion free reinforcement also gives more time for maintenance crews to identify and repair sections of shotcrete when cracking does occur.

2. Increased Toughness

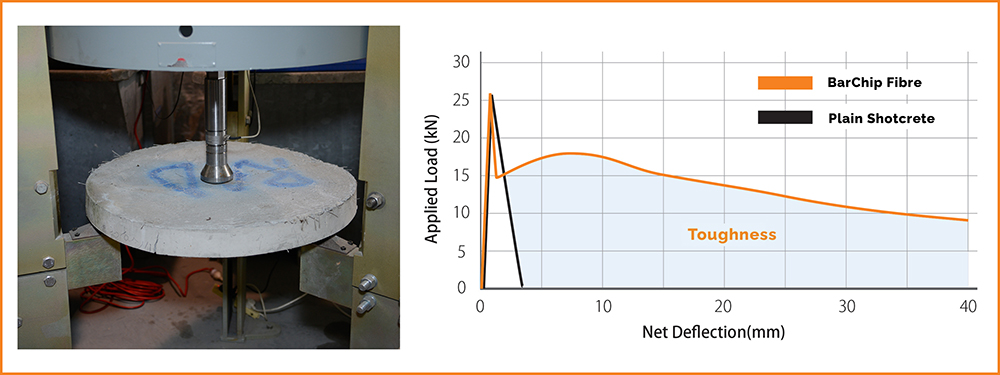

Testing shows that BarChip synthetic fibre significantly improves the post crack residual strength of shotcrete. Even at very large deformations, BarChip fibres continue to impart residual capacity on shotcrete.

The increased toughness is especially critical in tunnelling, mining, and underground construction, where ground conditions can be unpredictable. With BarChip fibres, shotcrete becomes more capable of adjusting to these conditions without losing its structural integrity.

ASTM round determinate panel test of fibre reinforced shotcrete.

3. Less Shotcrete Needed

Shotcrete is an ideal solution for irregular surfaces and complex geometries, as it can be sprayed directly onto the substrate and follows the natural contours of the ground. When using steel mesh, voids behind the mesh must be filled to achieve the required shotcrete cover, which leads to a significant increase in the volume of shotcrete used compared to fibre reinforced shotcrete. Replacing mesh with BarChip fibre not only reduces material consumption but also leads to faster application, making construction times shorter. Furthermore, synthetic fibres like BarChip do not present a risk from protruding fibres and can allow designers to eliminate protective shotcrete layers. This can result in an additional 5 cm reduction in lining thickness.

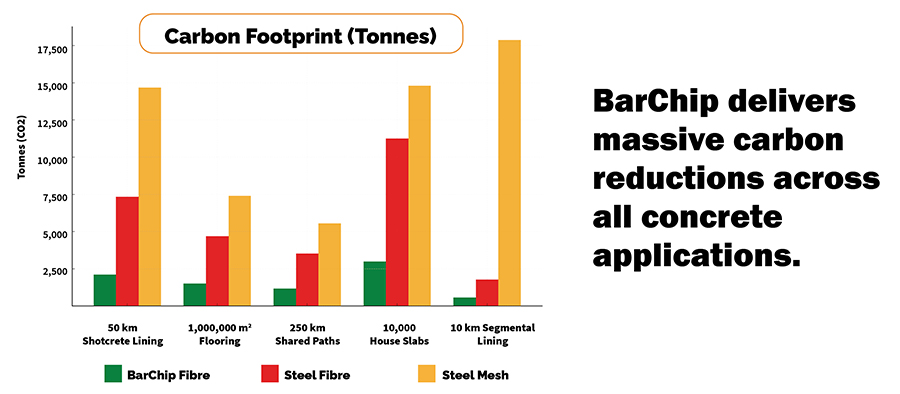

4. Reduced Carbon Footprint

By replacing traditional steel mesh or fibre reinforcement with BarChip macro synthetic fibres, projects can significantly reduce their carbon footprint. Steel production is energy intensive, resulting in a higher carbon footprint compared to macro synthetic fibre reinforcement like BarChip. Depending on the application, the carbon reduction obtained by using synthetic fibre can be substantial. Additionally, when compared to steel mesh, synthetic fibre reinforced shotcrete can reduce the overall volume of shotcrete used, which in turn further reduces carbon footprint. These factors make BarChip fibre reinforced shotcrete a low carbon solution for many modern construction projects.

5. Low Cost

Using BarChip fibres in shotcrete delivers direct cost and time savings. Unlike steel mesh, which requires labour intensive and time consuming installation, BarChip fibres are mixed directly into the shotcrete and sprayed onto the substrate. This simple installation process reduces labour costs. Additionally, the elimination of corrosion means that the shotcrete does not require expensive protective treatments or maintenance, further lowering overall project costs. The time saved during construction and the reduced need for ongoing maintenance translate to significant long term savings, making BarChip fibre reinforced shotcrete a cost effective alternative to steel reinforced shotcrete systems.

Conclusion

BarChip fibre reinforced shotcrete provides numerous advantages, from corrosion free durability and increased toughness to sustainability and cost effectiveness. Its ability to follow the contours of the ground and reduce the need for excess material also makes it an efficient solution, especially in tunnelling and underground construction. By choosing BarChip fibres, you not only improve the structural performance and durability of your shotcrete but also reduce the environmental impact and lower costs.

BarChip’s Technical Team has learned experience spanning hundreds of tunnels across 4 continents and is always here to support you. Whether it’s fibre selection, design optimization, mix design or help during construction, our team is ready to help. Tell us about your project today.