Low Carbon Concrete: Reducing the Carbon Footprint of Reinforcement

Sustainable construction is one of the defining challenges of our time, and low carbon concrete is at the heart of the solution. Concrete is the world’s most widely used building material, but its production contributes heavily to global carbon emissions. Engineers, contractors, and asset owners are increasingly searching for low carbon concrete solutions to meet climate targets and deliver more sustainable infrastructure.

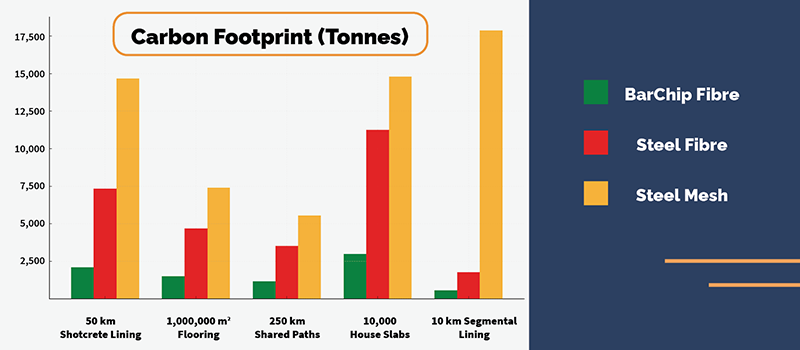

While cement often gets the spotlight, reinforcement also plays a critical role in the carbon footprint of concrete. That’s where BarChip macro synthetic fibre makes a measurable difference.

Why Reinforcement Matters in Low Carbon Concrete

The embodied carbon of steel reinforcement is significant. Manufacturing mesh, rebar and steel fibre requires high temperatures, large amounts of energy, and significant water use, making steel production responsible for around 7–9% of global CO₂ emissions.

When we talk about low carbon concrete, we cannot ignore the reinforcement. By rethinking reinforcement methods, we can cut a meaningful portion of embodied carbon, without changing the performance requirements of the structure.

Fibre Reinforcement as a Sustainable Alternative

Macro synthetic fibre reinforcement offers a sustainable, corrosion free alternative to traditional steel. Unlike steel mesh, BarChip fibres:

- Require far less energy to manufacture.

- Eliminate corrosion risk, extending service life and reducing maintenance.

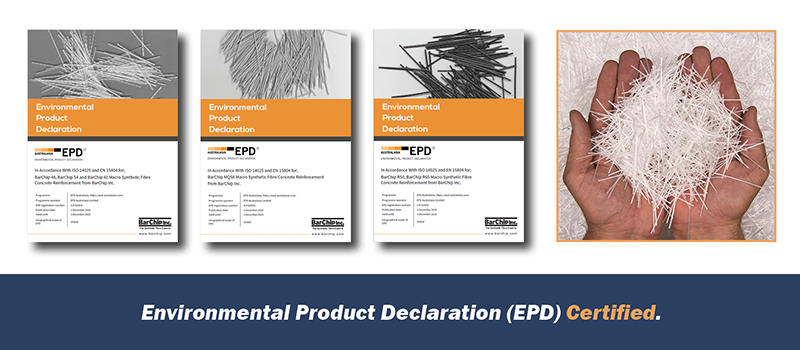

This makes fibre reinforced low carbon concrete a practical solution available today. With EPD certification (ISO 14025, EN 15804), BarChip provides transparent, verifiable sustainability data to support infrastructure ratings and carbon assessments.

How BarChip Fibre Delivers Low Carbon Concrete Solutions

BarChip reduces carbon at every stage of concrete use. Its benefits extend from material production to lifecycle performance, delivering measurable savings across multiple project areas:

Reducing Reinforcement Emissions – Steel production is energy intensive and a major source of carbon. By replacing steel mesh and steel fibre, BarChip avoids the emissions tied smelting and transporting heavy reinforcement. Every tonne of steel replaced represents a significant saving in embodied carbon, making fibre reinforcement one of the fastest ways to lower the footprint of concrete structures.

Enabling Performance Based Designs – Because BarChip is corrosion free, engineers no longer need to add extra concrete cover to protect reinforcement from rust. This allows designs to be based purely on structural performance, rather than durability limits, often reducing the total volume of concrete required. In precast elements especially, this approach enables slimmer sections without compromising strength, durability or service life.

Reducing Shotcrete Thickness – Traditional mesh reinforced shotcrete requires voids behind the mesh to be filled, which increases material use. With fibre reinforcement, the shotcrete can follow the ground profile in a uniform layer, creating an even thickness. This avoids unnecessary overbuild and results in notable reductions in the total volume of shotcrete applied, improving cost, efficiency and sustainability.

Lowering Transport Emissions – Steel mesh is bulky, heavy and difficult to transport, often requiring multiple truckloads to service a single project. BarChip, by contrast, is compact and lightweight, allowing large volumes to be delivered in a fraction of the trips. Fewer deliveries reduce site traffic, cut fuel consumption and lower transport related carbon emissions.

Minimising Maintenance – Maintenance is a major hidden contributor to the lifecycle carbon footprint of concrete structures. With no steel to corrode, BarChip eliminates costly repairs caused by rust and corrosion induced cracking. Structures reinforced with fibre remain durable over decades of service, reducing the need for interventions and significantly lowering carbon and cost over their lifetime.

Together, these benefits show how BarChip fibre contributes as the industry transitions towards low carbon concrete solutions.

Applications of Fibre Reinforced Low Carbon Concrete

Precast Concrete – By removing the need for steel reinforcement, BarChip enables optimised precast designs. Without concrete cover requirements, sections can often be thinner, reducing concrete use while maintaining performance.

Shotcrete and Tunnelling – Fibre reinforced shotcrete follows the ground profile in a consistent thickness, avoiding the overspray required with steel mesh. This reduces shotcrete use while maintaining strength and improving safety underground.

Concrete Track Slab – Fibres eliminate the need for heavy steel reinforcement in concrete track slabs, streamlining construction and reducing installation time. By removing corrosion risk, BarChip improves long term durability, while the substantial weight of steel replaced delivers significant reductions in embodied carbon.

Concrete Flooring – In large slabs, BarChip replaces carbon heavy steel mesh with low carbon fibre reinforcement. This substitution delivers significant reductions in embodied carbon while maintaining strength and durability.

Concrete Paving – In application such as road pavements, BarChip works with Thin Concrete Pavement (TCP) designs to reduce slab thickness. Across the length of a highway, this reduction in concrete use translates into major carbon savings.

Verified Sustainability Through EPD

BarChip macro synthetic fibres are EPD certified, meaning their environmental performance is independently verified. This gives designers and contractors confidence that their sustainability claims are backed by transparent data.

With BarChip, projects can earn credit in infrastructure sustainability schemes such as:

- IS Rating Tool (Australia & NZ) – Mat-1, Rso-6, Rso-7

- Green Building certifications – through documented carbon reductions

- Global carbon reporting – by showing measurable savings against steel reinforcement

Building a Low Carbon Future with Fibre Reinforcement

The path to low carbon concrete isn’t only about changing cement chemistry. It’s also about smarter reinforcement choices that cut embodied carbon and enable more efficient designs.

By eliminating steel reinforcement, reducing material use, lowering transport needs and extending service life, BarChip fibre helps deliver practical, proven low carbon concrete solutions today.

Low carbon concrete is here. BarChip fibre makes it possible.