What is Fibre Reinforced Concrete (FRC)? A Beginners Guide

Fibre Reinforced Concrete (FRC) is a composite material made from concrete and fibrous elements, such as macro synthetic or steel fibre. Fibres are typically used to improve the post crack residual strength of concrete, or as plastic shrinkage cracking control. Concrete fibre reinforcement, like BarChip, also improves other properties of hardened concrete, including durability, impact resistance, seismic resistance, crack width control, and can replace traditional reinforcement in concrete. This innovative approach to concrete reinforcement has gained popularity in construction due to its performance, ease of use and low cost.

How Fibre Reinforced Concrete Works?

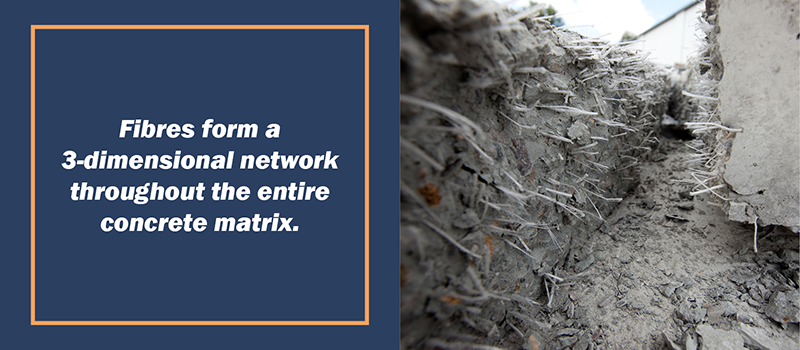

Fibre Reinforced Concrete works by distributing thousands of fibres uniformly throughout the concrete mix. When the concrete hardens, the fibres form a network that distributes load and restricts the development of cracks.

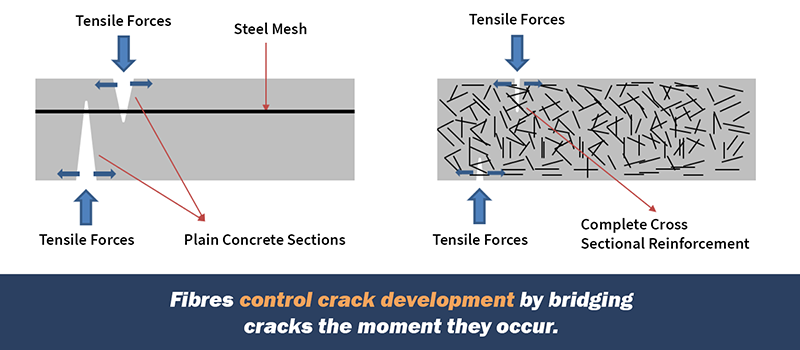

In traditional reinforced concrete, steel is placed in the top or bottom third , with the remainder of the concrete cross section being plain concrete. As cracks form, they must travel through the unreinforced sections of concrete before being controlled by the steel.

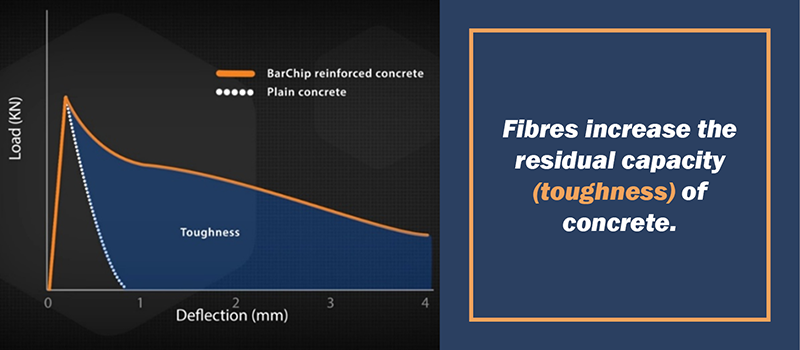

In fibre reinforced concrete, the fibres are mixed throughout the entire concrete element and bridge cracks the moment they start to form, delaying and even preventing the development of micro cracks into macro cracks. This bridging effect is one of the main benefits of fibre reinforced concrete, providing a 3-dimensional reinforcement system that controls crack development throughout the entire cross section to deliver improved toughness and durability.

Why Concrete Fibres are Used Over Traditional Steel Mesh Reinforcement?

Fibre Reinforced Concrete offers several advantages over traditional steel reinforcement. These include:

- Enhanced Toughness: Fibres increase the post crack residual capacity (toughness) of concrete and shotcrete.

- Improved Crack Resistance: Fibres can bridge cracks at the exact formation of micro cracking, improving crack resistance compared to normal concrete.

- Corrosion Free: BarChip fibre is corrosion free and gives superior resistance in harsh environments, resulting in longer-lasting concrete structures.

- Low Cost: BarChip eliminates the construction time and labour cost associated with installing steel mesh reinforcement, which can significantly reduce overall construction costs.

- Low Carbon: Depending on the application, BarChip regularly reduces the carbon footprint by 50% to 80% compared to traditional steel reinforcement.

- Ease of Use: Incorporating fibre reinforcement directly into the concrete mix is simpler and easier than placing and securing steel reinforcement.

- Versatility: Fibre reinforced concrete can be used with irregular shapes and surface contours without limiting performance.

What Types of Fibres are used in Fibre Reinforced Concrete?

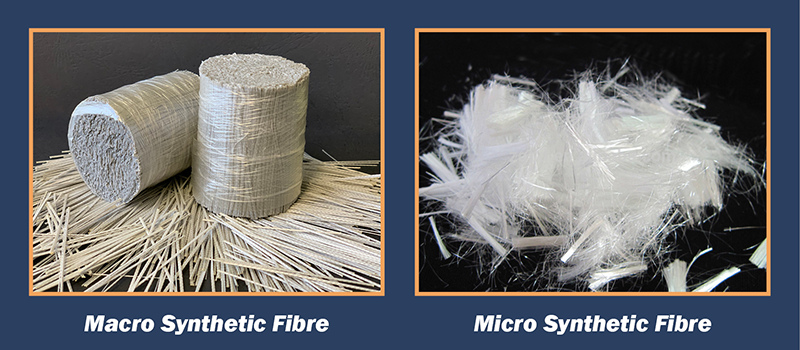

1. Synthetic Fibres: Synthetic fibres, such as polypropylene and polyethylene, provide excellent resistance to cracking and improve the concrete’s post crack residual strength, also known as toughness. They are high performance, corrosion free and cost effective, making them suitable for a wide range of concrete applications. There are two main types of synthetic fibre:

a. Micro Fibres: Micro synthetic fibres (diameter is <0.3mm) are very fine hair like fibres used for control of plastic shrinkage cracking or to reduce explosive spalling in fires. Micro fibres have no effect on hardened concrete and cannot be used to control cracking induced by load or drying shrinkage.

b. Macro Fibres: Macro synthetic fibres (diameter is ≥0.3mm) deliver post crack residual strength to concrete and shotcrete and are suitable to use as crack control or structural reinforcement in concrete. With the use of macro synthetic fibres, traditional steel reinforcement can be replaced in many applications.

2. Steel Fibres: Steel fibres are widely used due to their high tensile strength. Like macro synthetic fibres, they improve the residual strength of concrete, making them suitable for crack control and structural reinforcement in concrete. Steel fibre is very susceptible to corrosion and as a result requires crack widths to be limited to as little as 0.1mm for durability concerns. Synthetic fibres are not subject to corrosion and are therefore not restricted by such demanding performance requirements.

3. Glass Fibres: Glass fibres are durable, chemical resistant, light weight and are commonly used in cladding, architectural mouldings and landscape elements. Unlike GFRP bars, glass fibres do not provide enough residual capacity to be suitable for use as concrete reinforcement in applications like flooring, precast elements or shotcrete ground support.

4. Basalt Fibres: Basalt fibres are high strength, lightweight and durable, making them suitable for use as concrete reinforcement. Basalt fibres can be a good engineering solution for high performance applications. However, due to the high cost of production they are not economically feasible for most projects and applications.

5. Natural Fibres: Natural fibres, such as bamboo, coconut coir, sisal and jute have been used in concrete & mortar for an age, long before the invention of steel reinforcement. Natural fibres can affect the properties of concrete, however, they do not really improve the residual capacity of hardened concrete and are not used as crack control or structural reinforcement in concrete.

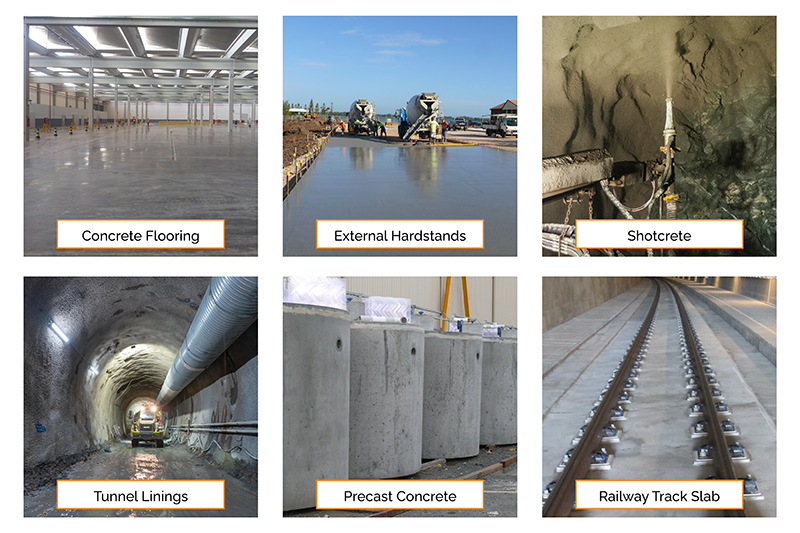

Where is Fibre Reinforced Concrete Used?

Concrete fibres are used across virtually every sector of construction, from mining to civil infrastructure, manufactured concrete and residential paving. Some of the most common applications include tunnel linings, precast concrete elements, commercial flooring, railway track slabs, slope stabilisation, external hardstands and road pavements.

Over the past 30 years, BarChip fibre has reinforced millions of square metres of concrete flooring, hundreds of civil tunnels and mine developments across Australia, North and South America, Europe and Asia. BarChip has reinforced concrete track slabs in more than a dozen light rail and metro projects, hundreds of kilometres of concrete roadways and countless precast concrete elements.