Fibre Reinforced Monolithic Slab – Morningstar Storage

BarChip fibre reduced reinforcement carbon footprint by 75% in Morningstar’s new monolithic slab, eliminated 37,000 lbs of steel and shortened construction time for the contractor.

BarChip fibre reduced reinforcement carbon footprint by 75% in Morningstar’s new monolithic slab, eliminated 37,000 lbs of steel and shortened construction time for the contractor.

In total, 438.7 tonnes of steel reinforcement was replaced with just 19 tonnes of BarChip48 macro synthetic fibre. Along with simplified logistics and faster construction, this change resulted in a direct carbon reduction of 900 tCO2-eq.

Find out how BarChip fibre enables low carbon concrete by eliminating steel reinforcement, reducing material use and supporting efficient, durable designs that cut embodied carbon across every stage of construction.

The global push to decarbonise steel is facing setbacks, with rising costs and infrastructure challenges stalling major projects. This industry insight explores why low-carbon steel remains a long-term challenge and highlights macro synthetic fibres as a proven, immediate alternative for sustainable concrete reinforcement.

Sustainable construction demands more than low carbon. This article highlights 7 ways BarChip fibre enables sustainable concrete solutions that deliver measurable sustainability outcomes across the life cycle of concrete projects.

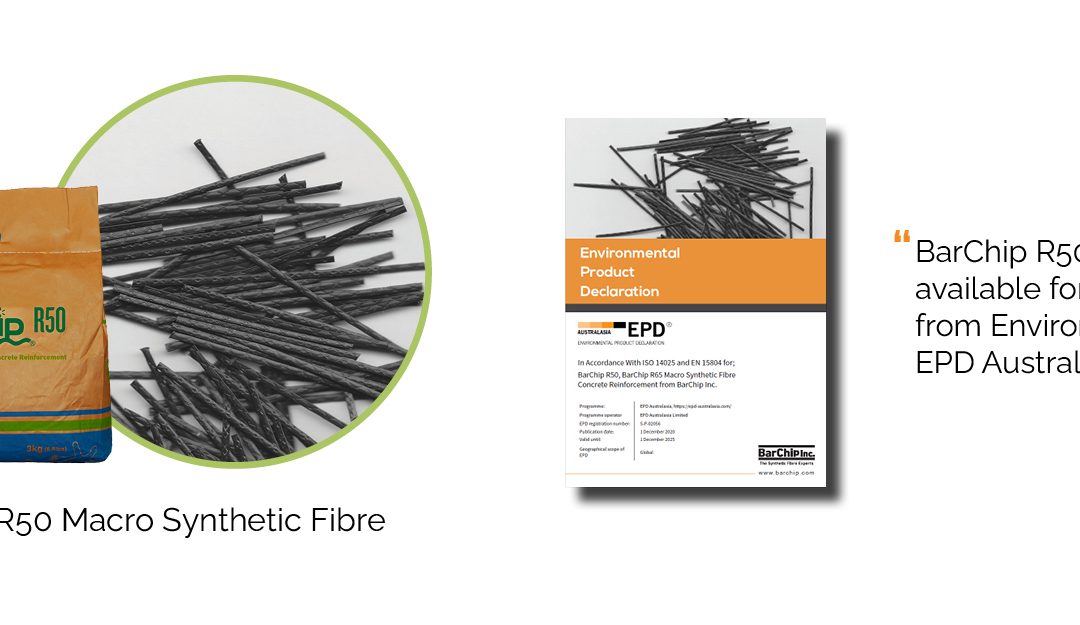

BarChip’s low carbon reinforcement has been independently certified by the International EPD System. Download the BarChip EPDs here.