Reinforcing More Than 450 Road, Rail and Utility Tunnels

Our fibres reinforce sprayed, cast and precast tunnel linings.

Build Smarter, Faster and More Sustainable Tunnels with BarChip Fibre.

BarChip macro synthetic fibre is used to reinforce shotcrete and concrete tunnel linings, replacing labour intensive and carbon heavy steel alternatives. BarChip fibres deliver unmatched strength, durability and sustainability for all tunnelling applications.

BarChip fibres adapt seamlessly to any ground condition, mix design or project process. Whatever your challenges with fibres for tunnels, our expert team has the answers you need.

Shotcrete Tunnel Linings

BarChip fibre eliminates the risk of corrosion in temporary and permanent shotcrete tunnel linings. Furthermore, BarChip eliminates the need to install steel mesh reinforcement, a labour intensive process that can consume up to 30% of the excavation cycle time and also requires workers to operate under unreinforced ground.

Cast In-Situ Linings

BarChip macro synthetic fibres are used in cast in-situ tunnel linings, either as the sole reinforcement or in combination with steel or GFRP reinforcement. When BarChip fibres are incorporated into the primary lining, a load-sharing design can potentially allow for a reduction in the thickness of the final lining. Designers may also be able to reduce cast lining thickness in situations where additional concrete cover is required to protect steel from corrosion.

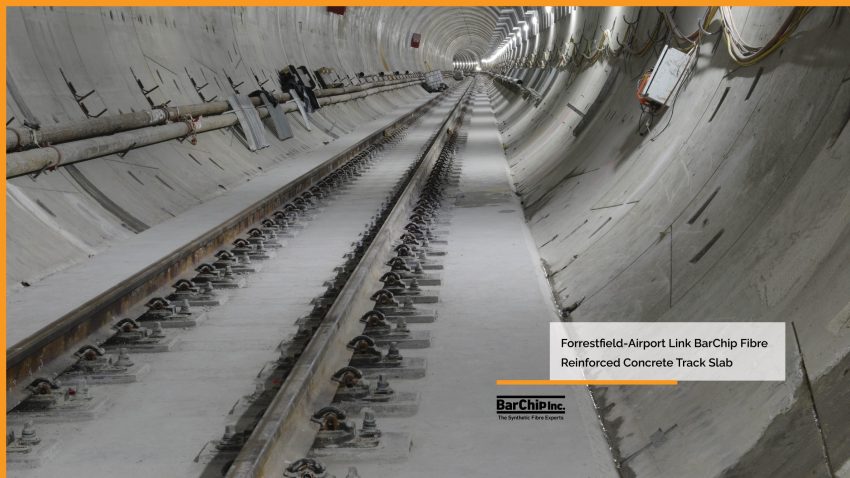

Invert Segments

BarChip fibres are a proven solution for invert segments. BarChip makes the production process faster and easier, while simultaneously delivering performance and durability benefits to the finished product.

Slope Stabilisation

The installation of steel mesh at portal openings, high walls and cuttings is a time-consuming and often dangerous activity. Using BarChip reinforced shotcrete eliminates this hazard while providing the most effective solution against rockfall and erosion.

BarChip Fibre is reinforcing more than 450 road, rail and utility tunnels around the world.

The Trusted Fibre for Tunnelling

For nearly three decades, BarChip has been the trusted fibre for tunnelling projects, chosen by the world’s largest and most respected construction companies for its proven performance and reliability in the most demanding conditions.

Designed to International Standards

BarChip fibres comply with leading international standards, ensuring reliable performance and compatibility with global engineering design guidelines for tunnelling projects.

Project Highlights

Frequently Asked Questions

Can BarChip fibre reinforce tunnel linings?

What type of tunnels does BarChip fibre reinforce?

BarChip macro synthetic fibre is currently reinforcing more than 450 civil tunnels, including road and rail tunnels, water and electrical utility tunnels, hydroelectric, pedestrian, storage and service tunnels.

Where are macro synthetic fibres used in tunnelling?

Why are synthetic fibres used in tunnel construction?

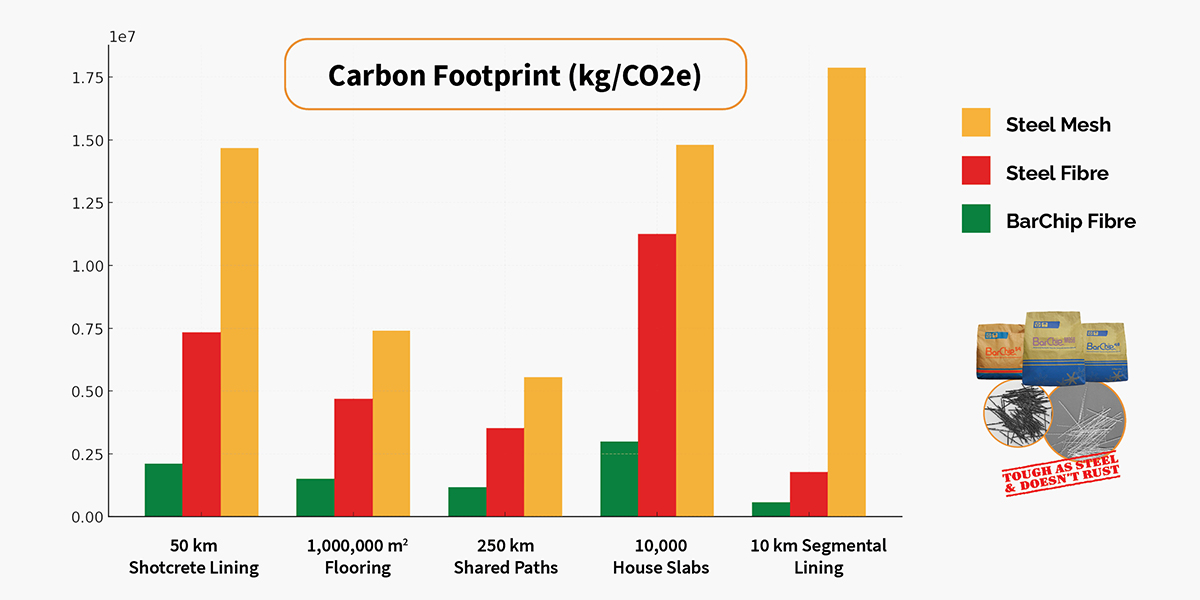

Does BarChip reduce the carbon footprint of tunnelling works?

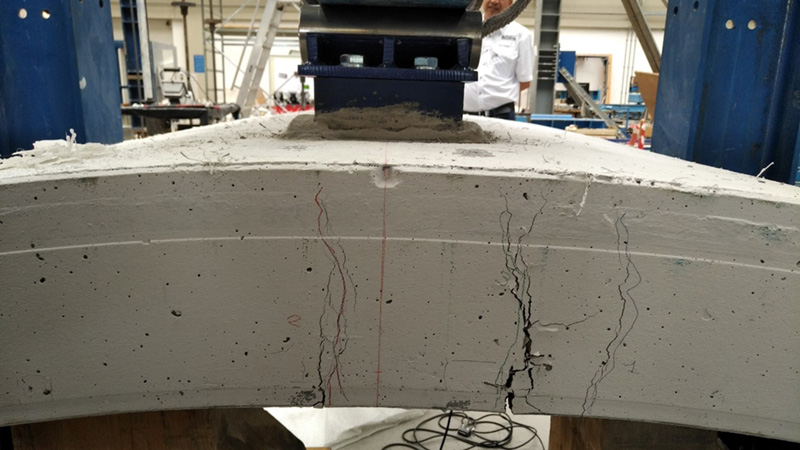

Can Synthetic Fibre replace steel in tunnel segments?

What is the best fibre for tunnel design?

The best fibre will depend on the application and design of the tunnel. BarChip has different fibres for each application, with the best fibre determined by the concrete mix and performance requirements of the structure.

How do fibres improve the safety of tunnelling works?

Mechanically applied fibre reinforced shotcrete, as a temporary or permanent lining, almost entirely removes the risk of loose rock fall and eliminates the need for workers to operate beneath unsupported ground.

Get in touch for a personal information session about your next project. One of our concrete fibre experts will guide you through the following 4 keys items: