Caldecott Fourth Bore Tunnel: An Innovative NATM Design

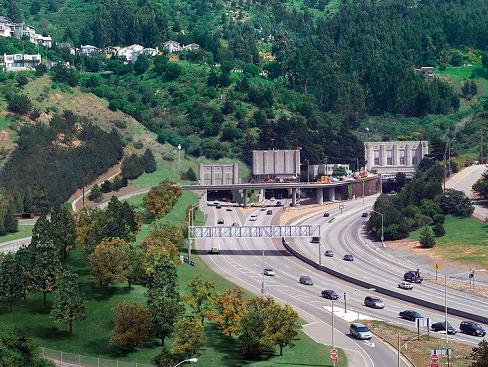

The Caldecott Fourth Bore Project is a 1,030m long, 15.2m wide, US$420 million highway tunnel in the San Francisco Bay Area owned by the California Department of Transportation. The main contractor was the Tutor-Saliba Corporation, and the preliminary and final designs were provided by Jacobs Associates. The tunnel used the New Austrian Tunnelling Method (NATM).

This project has added a Fourth Bore to the existing Caldecott Tunnel, allowing for two bores to be permanently open in each direction to help ease the congestion created by 160,000 daily commuters.

The Caldecott Fourth Bore Tunnel encountered four major inactive fault lines through rock mass varying from blocky at best down to a disintegrated or crushed condition in the poorest quality rock, with a rock mass rating expected to be between 20 and 65 along the alignment. 1.4km west of the tunnel is the Hayward Fault, capable of producing a 7.4 magnitude earthquake. Seismic analysis was based around a 1500-year return period for SEE events and 300-year return period for FEE events.

The rock mass properties around the Caldecott Fourth bore are as follows;

- Geological Strength Index (GSI): 26

- Unconfined compressive strength of of intact rock (UCS): 5.3MPA (800psi)

- Hoek-Brown constant mi: 7

- Mohr Coulomb friction angle: 30 degrees

- Cohesion: 65 kPa (1,350 psf)

- Undrained sheer strength: Su (kPa) = 7.35(z) + 38.5 (kPa) or Su (psf) = 153(z) +804 (psf)

Ground support for the initial shotcrete lining comprised of Barchip’s macro synthetic fibers and rock bolts. After successfully using BarChip in the Devils Slide Tunnel the California Department of Transportation (Caltrans) was confident BarChip could meet Caldecott’s ground support and seismic performance requirement.

In NATM tunnels the role of the initial lining is to “to carry the ground loads, control the ground deformations during tunnel construction, and provide a safe work environment,” typically, this lining is considered redundant after construction. It is the role of the secondary lining to “support the long term ground loads, hydrostatic loads where applicable, and any additional loads resulting from finishes or anchored equipment. The secondary lining also provides a permanent lining for fire protection.”

However, BarChip synthetic fiber reinforced initial lining can support a significant portion of the long-term ground loads. Indeed, in many tunnels a permanent sprayed concrete lining is all that’s required. By allowing load sharing between the initial and secondary lining designers can reduce the design loads on the on the secondary lining which can result in significant cost savings.

The paper ‘Load Sharing in Two Pass Lining for NATM Tunnels,’ published by Jacobs engineers, discusses “the basic principles of load sharing in two-pass lining systems and proposes a rational method for design.” This paper is available for download below and presents the Caldecott Fourth Bore as case study of the benefits of Load Sharing in NATM tunnels.

The Caldecott Fourth Bore used 19,732 cubic metres of Barchip fiber reinforced shotcrete which included a 200mm-300mm thick initial shotcrete lining and a 50mm-100mm thick shotcrete face lining. Designers were confident that this lining had the ability to withstand long term ground loadings and as such designed the secondary lining to only need to carry 67% of the long term ground load. Engineers still felt this was a conservative design.

By designing the secondary lining to carry 67% of the ground load rather than 100% designers were able to reduce the secondary linings required thickness by 30% resulting in a significant cost saving. Furthermore, an additional benefit of the reduced secondary lining thickness was the reduction in forces in the more flexible lining when subject to seismic racking deformations.

Overall this project was an incredible success, was completed on time and came in under budget. These successes can largely be attributed to the innovative load sharing design that was used in this tunnel.

Click here to download ‘Load Sharing in Two Pass Lining for NATM Tunnels.’

This document, published by Jacobs engineers, discusses “the basic principles of load sharing in two-pass lining systems and proposes a rational method for design.”