BARCHIP FIBRE REINFORCED

CONCRETE TRACK SLAB

BarChip 48 Reinforcing 45 km of Fibre Reinforced Concrete Track Slab in Istanbul’s New M11 Metro Line

Currently under construction, Turkey’s 1 billion Euro M11 metro line will be one of the longest metro lines in the world at a total of 69 km. The line has a maximum speed of 120 km/h (75 mph) and is expected to carry over 90 million passengers annually. A key component of the project is the 31.5 km Halkali Metro Tunnel, running from Halkali to Instanbul Airport.

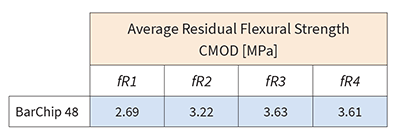

To improve durability and construction efficiency, the design team specified a synthetic fibre reinforced concrete track slab. Two seperate accredited labs in Istanbul tested a variety of fibre options according to EN 14651 Notched Beams, with 5.5 k/m3 of BarChip 48 proving to be the best fibre. The achieved results that ultimately won the project can be seen in the table below.

The design team highlighted 4 key reasons for specifying a macro synthetic fibre solution.

- It eliminated corrosion and increased concrete durability

- It increased impact strength

- It increased fatigue strength

- It reduced construction time

All up, 167 tonnes of BarChip was used to reinforced 45 km of concrete track slab, which also delivered a significant carbon reduction vs. traditional reinforcement. An example of the carbon benefit achieved with BarChip fibre can be seen on the Parramatta Light Rail Track Slab, where 101 tonnes of BarChip replaced over 2,426 tonnes of steel bar for a carbon saving of over 4,800 tonnes of CO2e.

Halkali metro joins a growing list of rail tunnels using BarChip fibre reinforced track slab, including Sydney Metro, New York Metro, Forrestfield-Airport Link, Cross River Rail and Bukit Berapit.